Call us

Features

PPEPL Composite Silicone rubber Insulators have qualified in 1000hrs Tracking and Erosion test as per IEC 62217 at CPRI.

The PPEPL Composite Silicone rubber Insulators meet the requirements of IEC: 61109, IEC:60815, IEC: 62217 and any relevant Standards.

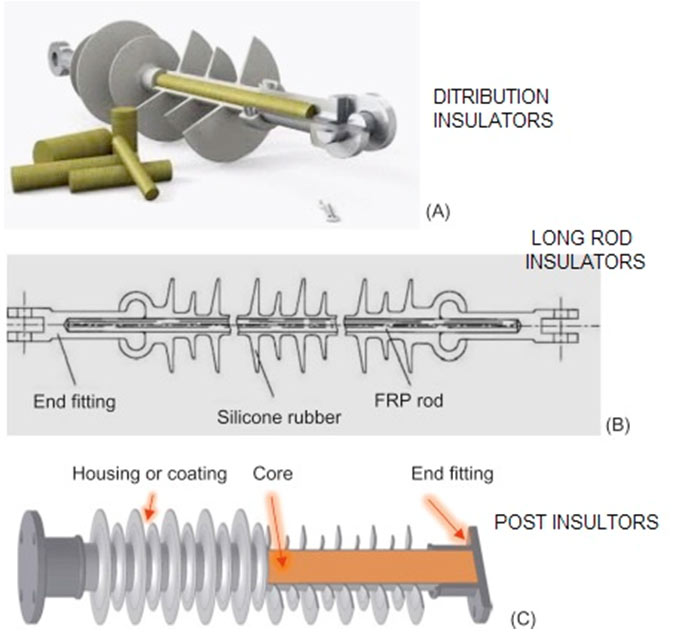

FRP core Rods are manufactured in –house using ECR grade Glass Fiber and high quality Epoxy Resin System from global suppliers use of good quality Silicone rubber from established suppliers.

Production

Pioneer has the latest European designed machines such as Injection Moulding, computer controlled crimping etc for the production of Silicone composite Insulators.

The machines and moulds are capable of manufacturing world class insulators that have uniform -- thickness across the length and are impenetrable to moisture and humidity thereby ensuring long service life

Testing

|

Electro |

Mechanical | Thermal | Chemical | Others | |

| ADVANTAGES | No Cleaning , No Maintenance |

Safety | No effect by Thermal Shock |

Hydrophobicity | Low Life Cycle cost |

| Safety | Low weight | Manufacturing flexibility | |||

| Design Flexibility | NO breaking | Not Fragile | |||

| High Performance under Pollution |

Resistance to Vandalism |

Easy Handling and Installation | |||

| ONE Single piece no joints in the core. | Resistance to seismic shocks |