Call us

EPC Projects

HAMPS FOOD PROCESSING UNIT @ chitoor

We successfully complted food processing unit for HAMPS FOOD PROCESSING with good facility where raw ingredients are transformed into consumable food products through various methods such as cleaning, cooking, freezing, or packaging. Building a food processing unit involves the design and integration of modern equipment, ensuring hygiene standards, and adhering to food safety regulations. The unit must be designed to optimize efficiency, minimize waste, and maintain the nutritional quality of the food. It should also incorporate sustainable practices like energy conservation and waste management, ensuring compliance with both local and international food processing standards.

APCPDCL VIJAYAWADA SUBSTATIONS

We successfully complted substation in a critical component of the electrical grid, designed to step down high-voltage electricity from power plants to lower voltage levels suitable for distribution to homes and businesses. Building a substation involves the careful planning and installation of transformers, switchgear, circuit breakers, and control systems, ensuring efficient and reliable energy transmission. The design must prioritize safety, scalability, and resilience, considering factors like load demand, location, and environmental impact. Adherence to industry standards and regulations is essential to ensure the substation operates optimally and supports the long-term stability of the electrical grid.

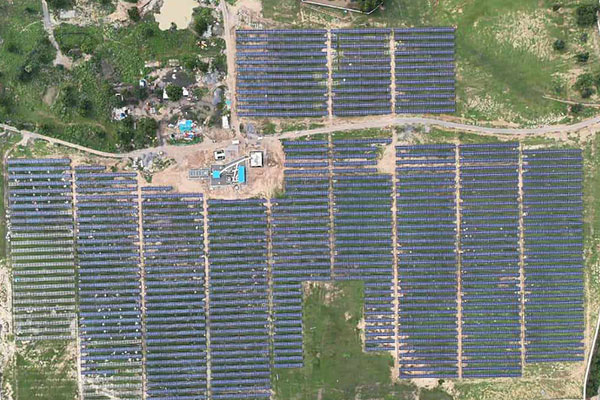

BHEL/SCCL MANUGURU 50 MW SPV ROADS

We successfully complted substation in a critical component of the electrical grid, designed to step down high-voltage electricity from power plants to lower voltage levels suitable for distribution to homes and businesses. Building a substation involves the careful planning and installation of transformers, switchgear, circuit breakers, and control systems, ensuring efficient and reliable energy transmission. The design must prioritize safety, scalability, and resilience, considering factors like load demand, location, and environmental impact. Adherence to industry standards and regulations is essential to ensure the substation operates optimally and supports the long-term stability of the electrical grid.

Various prestressed precast boundary wall projects

Precast boundary wall projects involve the use of factory-made concrete panels that are assembled on-site to create durable and secure walls. These walls offer a quick, cost-effective solution for defining property boundaries while maintaining high structural integrity. With precision casting and easy installation, precast boundary walls are ideal for both residential and commercial applications. They also provide flexibility in design, strength, and low maintenance, making them a reliable choice for clients seeking efficient and long-lasting boundary solutions.